Nothing ruins a Saturday morning like pulling the starter cord on your lawn mower and getting no response. Engine issues can turn yard maintenance into a frustrating ordeal, but most lawn mower complications stem from a handful of common causes. You can diagnose and fix many of the issues yourself. Understanding how to troubleshoot lawn mower engine problems systematically will save you from the delay and cost of calling a repair shop for every minor hiccup.

Check the Fuel System

Fuel-related issues cause most engine problems. Start the diagnostic process by examining the fuel system.

Old gasoline breaks down over time, creating gummy deposits that clog fuel lines and carburetor jets. Drain any fuel that has sat in your mower for more than 30 days and replace it with fresh gasoline mixed with the appropriate oil ratio for two-stroke engines.

Check the fuel filter for clogs or debris that might restrict fuel flow to the engine. A dirty fuel filter will starve your engine of the gasoline it needs to run properly, causing poor performance or complete failure to start.

Fuel Delivery Problems

Fuel delivery issues prevent gasoline from reaching the carburetor, causing starting and running problems. Check the fuel cap vent to ensure it allows air to enter the tank as it consumes fuel. A blocked vent creates a vacuum pressure that prevents fuel flow to the carburetor. Examine fuel lines for cracks, kinks, or clogs that restrict gasoline flow, and replace damaged lines immediately.

Examine the Air Filter

A clogged air filter restricts airflow to the engine, creating a rich fuel mixture that prevents proper combustion. Remove the air filter housing and inspect the filter element for dirt, grass clippings, and debris buildup.

If your engine uses paper filters and they’re dirty, you should replace them. For mowers with foam filters, you can clean them with warm, soapy water, then re-oil them before reinstalling. Clean air filters allow your engine to breathe properly, maintaining the correct air-to-fuel ratio for optimal performance. Replace air filters at the beginning of each mowing season to prevent airflow restrictions.

Inspect the Spark Plug

The spark plug provides the electrical ignition needed to fire the fuel mixture in your engine’s combustion chamber. Using a spark plug wrench, extract the spark plug and inspect the electrode for signs of carbon accumulation, oil residue, and significant wear.

A functional spark plug should have a light brown or tan electrode tip. Black, oily deposits indicate a rich fuel mixture or oil burning, while white deposits suggest a lean mixture or overheating.

Quality lawn mower spark plugs by E3 Spark Plugs feature advanced electrode designs. They supply strong, consistent ignition for improved engine performance.

Spark Plug Gap Specifications

Check the spark plug gap using a feeler gauge, as incorrect gaps prevent proper ignition. Most lawn mower engines require a gap between 0.028 and 0.031 inches, but consult the owner’s manual for the precise specifications.

Adjust the gap by carefully bending the ground electrode, never the center electrode. Replace spark plugs annually or according to your engine manufacturer’s recommendations to maintain reliable starting and smooth operation.

Test the Ignition System

Beyond the spark plug itself, ignition system components can fail and prevent your engine from starting. To check the ignition coil, first take out the spark plug and hold its metal body against the engine. Then, pull the starter cord.

A healthy coil will produce a bright blue spark across the plug’s gap. Weak orange sparks or no spark at all indicate ignition coil problems that require professional replacement. Check all ignition wires for cracks, fraying, or loose connections that could interrupt the electrical flow to the spark plug.

Evaluate Carburetor Function

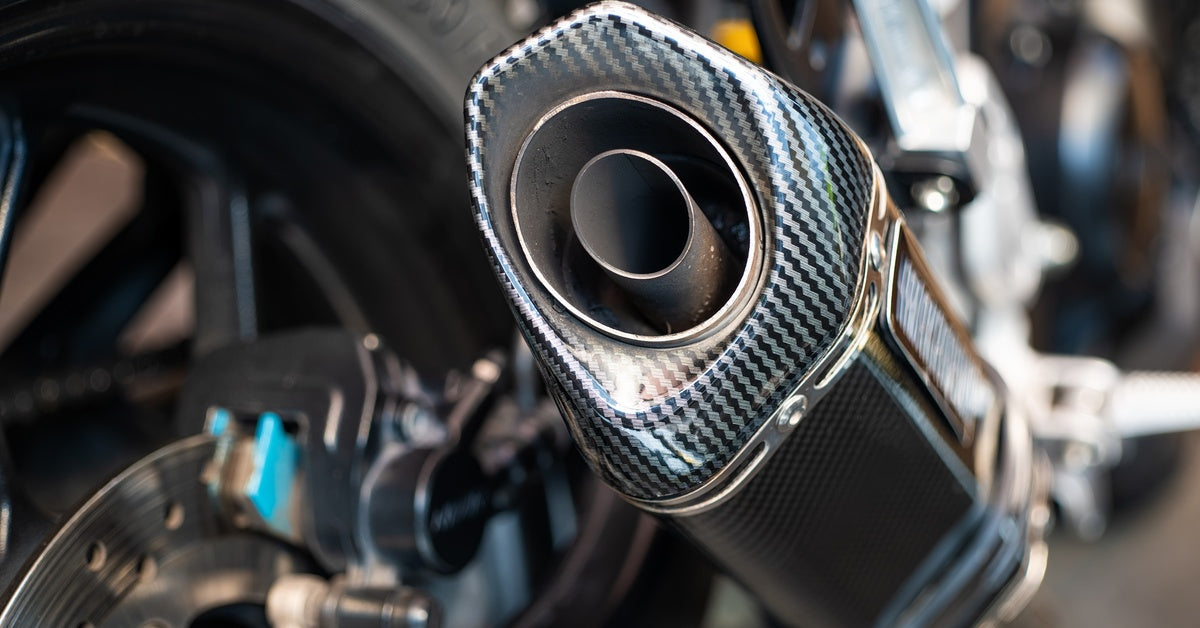

The carburetor mixes air and fuel in precise ratios for combustion, and carburetor problems frequently cause engine performance issues. Symptoms of carburetor trouble include hard starting, rough idling, stalling during operation, and black smoke coming from the exhaust.

Remove the air filter and spray carburetor cleaner into the air intake while the engine is running to see if performance improves temporarily. If cleaning only helps momentarily, you might need to rebuild the carburetor to remove fuel deposits and debris from internal passages.

Address Exhaust System Blockages

Blocked exhaust systems create back pressure that prevents proper engine operation and reduces power output. Remove the muffler and inspect it for carbon buildup or debris that restricts exhaust gas flow.

Clean carbon deposits using a wire brush and replace the muffler if internal baffles have deteriorated. Some engines feature spark arrestor screens that prevent sparks from escaping the exhaust, and these screens require periodic cleaning to maintain proper flow.

Check Engine Compression

Low compression prevents your engine from developing sufficient power to run properly, often resulting from worn piston rings, valves, or cylinder walls. Perform a compression test using a compression gauge threaded into the spark plug hole.

Most small engines should produce between 90 and 120 PSI of compression, though exact specifications vary by engine model. Extremely low compression readings indicate internal engine wear that requires professional repair or engine replacement.

Assess the Starter System

Starter system failures prevent the engine from turning over when you pull the recoil cord or press the electric start button. Inspect the starter rope for fraying or breakage, and check that the recoil spring returns the cord smoothly after each pull.

Remove the starter housing to examine the starter pawls that engage the flywheel during starting. Worn or broken starter pawls fail to turn the engine crankshaft, making starting impossible despite adequate fuel, air, and spark.

Examine Engine Oil Levels

Insufficient engine oil or contaminated oil causes internal engine damage and performance problems. Check the oil level using the dipstick. Add oil, if needed, but avoid overfilling as excess oil can cause smoking and poor performance.

Change engine oil regularly according to manufacturer recommendations, typically every 25 to 50 operating hours or annually. Dark, thick oil or oil containing metal particles indicates engine wear and the need for more frequent oil changes or professional inspection.

Investigate Cooling System Issues

Overheating damages engine components and reduces performance, often caused by blocked cooling fins or debris around the engine. Remove grass clippings, leaves, and dirt from cooling fins using compressed air or a soft brush.

Check that the engine shroud remains properly installed to direct cooling airflow over the engine. Overheated engines may shut down automatically to prevent damage, requiring cooling time before restarting.

Learning to troubleshoot lawn mower engine problems makes you a more confident equipment operator. Routine maintenance and installing high-quality parts can extend the life of your mower.

Make sure your mower delivers the performance you need every time. Explore E3 Spark Plugs today to keep your equipment running smoothly!